University of Twente [ 18 months ]

University of Edinburgh [ 18 months ]

Turn on Javascript!

Turn on Javascript!

Turn on Javascript!

I graduated from Technical University of Berlin in engineering science with a focus on continuum mechanics, as well as numerics and simulations. My master's thesis on 'relaxation behaviour of micropolar ferrofluids by means of homogenisation' builds the bridge to my current PhD project where I am working on up-scaling methods from discrete to continuum level of granular materials with regard of micropolar theory.

Throughout my studies, I always liked to broaden my horizon with various jobs as student assistant working on e.g., Virtual Reality, fiber composite component design, parameter-dependent automated mesh generation or plastic contact simulation. Moreover, I went on a two-semester long exchange to NTNU Trondheim, Norway.

You can also find me on LinkedIn.

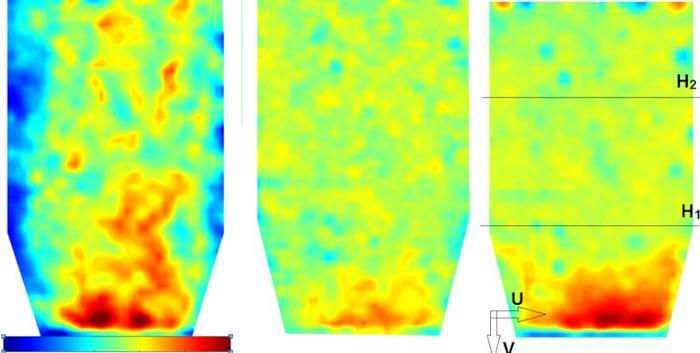

Due to their non-spherical shapes and contact friction, particles rotate or roll along and over each other. This project will properly add the rotational degrees of freedom to existing coarse graining methods, apply those to some particulate flow problems (like low-p flow and compaction situations) and evaluate for which of these situations an improved micro-polar or Cosserat-type continuum theory is needed.